Exploring the Wonders of Cryogenics:

From medical breakthroughs and space exploration to scientific research and environmental solutions, cryogenics plays a pivotal role in advancing technology and improving lives.

HISTORY OF CRYOGENICS

Exploring the Wonders of Cryogenics: From medical breakthroughs and space exploration to scientific research and environmental solutions, cryogenics plays a pivotal role in advancing technology and improving lives.

1823

MICHAEL FARADAY.

Michael Faraday's experiments demonstrated that gases could be liquefied, achieving temperatures around 173 K (-100 °C), laying the groundwork for cryogenic technology.

1869

CRITICAL TEMPERATURE DISCOVERY.

Thomas Andrews discovered the concept of critical temperature, above which the liquid state cannot exist regardless of pressure, through his experiments with CO2.

1877-1908

GAS LIQUEFACTION ADVANCES.

Key researchers such as Louis Paul Cailletet, Karol Olszewski, Zygmunt Wróblewski, James Dewar, and Heike Kamerlingh Onnes made significant advances in the liquefaction of gases like oxygen, air, hydrogen, and helium.

1892

DEWAR FLASK INVENTION.

James Dewar invented the vacuum flask, essential for storing cryogenic fluids, revolutionizing the storage and transportation of these materials.

1954

EFFICIENCY IN AIR LIQUEFACTION.

Philips scientists, including G.H. Kohler, developed an efficient air liquefier that provided refrigeration capabilities in the 20K range, significantly advancing cryogenic technology.

1959

G-M CYCLE INNOVATION.

Gifford and McMahon (G-M) modified the Stirling cycle, creating a system with a compressor, regenerator, and expansion device, enhancing the efficiency and capabilities of cryogenic systems.

21st Century

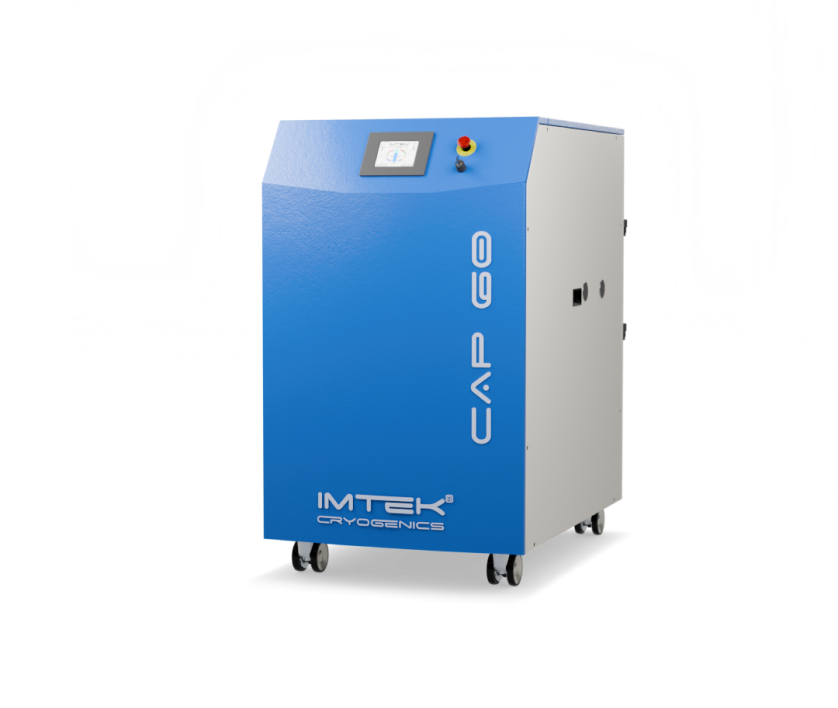

20 DECADES AT IMTEK CRYOGENICS

Cryogenics continues to advance with IMTEK Cryogenics at the forefront, developing more efficient cryocoolers for space exploration, military, and medical applications. Our cutting-edge technology supports quantum computing, cryogenic energy storage solutions, superconducting magnets, and cryopreservation, showcasing IMTEK Cryogenics' pivotal role in driving innovation across these critical fields.

Pioneering Cold Technology

At IMTEK Cryogenics, we specialize in the production and application of cryogens—substances used to achieve extremely low temperatures. Our advanced cryogenic solutions play a crucial role in a variety of industries, from medical and scientific research to space exploration and energy storage. Discover how our cutting-edge cryogenic technology is transforming the way we understand and utilize the power of cold.

Cryogenic Safety Guidelines

Ventilation:

Always use cryogenic liquids in well-ventilated areas. One liter of liquid nitrogen vaporizes to displace 694 liters of air, necessitating proper ventilation.

Pressure Management:

Ensure sealed containers have pressure relief mechanisms, as vaporization generates significant pressure.

Protective Gear:

Always wear proper gloves and protective gear to prevent skin burns and frostbite.

Proper Containers:

Use only containers designed for cryogenic liquids. Regularly inspect containers and pressure relief valves for defects.

Careful Handling:

Handle cryogenic liquids carefully to avoid burns. Brief exposure can damage delicate tissues like the eyes.

Slow Transfer:

When transferring or filling containers, do so slowly to minimize boiling and splashing. Use tongs for object retrieval from cryogenic liquids.

Careful Handling:

Handle cryogenic liquids carefully to avoid burns. Brief exposure can damage delicate tissues like the eyes.

Container Capacity:

Do not fill secondary containers beyond 80% capacity to allow for expansion.

Appropriate Tools:

Use wooden or rubber tongs for small items. Cryogenic gloves are for indirect or splash protection only, not for immersion.

Following these guidelines ensures safe handling and use of cryogenic liquids.

Glossary

Cryogenics

The study and application of extremely low temperatures on materials and phenomena.

Cryogenic Liquid

A liquid with a boiling point below -150°C (-238°F). Common examples include liquid nitrogen, liquid helium, and liquid hydrogen.

Dewar

A specialized container used to store and transport cryogenic liquids, designed to minimize heat transfer.

LN2 (Liquid Nitrogen)

A widely used cryogenic liquid with a boiling point of -196°C (-321°F), known for its versatility and efficiency as a refrigerant.

LHe (Liquid Helium)

A cryogenic liquid with a boiling point of -269°C (-452°F), used primarily in applications requiring extremely low temperatures.

LH2 (Liquid Hydrogen)

A cryogenic liquid used in various applications, especially as a propellant in rockets and space vehicles, with a boiling point of -253°C (-423°F).

Stirling Cryocooler

A cryocooler that uses the Stirling cycle for efficient cooling, often used in miniature cryogenic applications.

Gifford-McMahon (GM) Cryocooler

A cryocooler that separates the compression and expansion stages to achieve cryogenic temperatures, enhancing efficiency for industrial use.

PSA (Pressure Swing Adsorption)

A process to separate gasses from a mixture under pressure, according to molecular characteristics and affinity for an adsorbent material.

Cryopreservation

The process of preserving cells, tissues, or other biological constructs by cooling them to sub-zero temperatures.

Superconducting Magnet

A magnet made from materials that exhibit superconductivity, used in MRI machines and particle accelerators.

Cryogenic Energy Storage

Storing energy in the form of cryogenic liquids, such as liquid air or nitrogen, to balance energy supply and demand in renewable energy systems.

Adiabatic Expansion

Storing energy in the form of cryogenic liquids, such as liquid air or nitrogen, to balance energy supply and demand in renewable energy systems.

Joule-Thomson Effect

The temperature changes in a real gas (not ideal) when it is forced through a valve while kept insulated so that no heat is exchanged with the environment.

Recuperative Cycle

A process that uses heat exchangers to improve the efficiency of cryogenic systems by recovering heat.

Brayton Cycle

A thermodynamic cycle that describes the workings of a constant-pressure heat engine, commonly used in gas turbine engines and cryocoolers.

Pulse Tube Cryocooler

A type of cryocooler that uses oscillating gas flows to transfer heat, without moving parts in the cold region.

Vacuum Flask (Dewar Flask)

An insulating storage vessel that greatly reduces heat transfer to maintain the temperature of its contents.

Superfluidity

A phase of matter in which a fluid can flow with zero viscosity, often observed in helium-4 below 2.19 K.