Innovative Research and Development

IMTEK Cryogenics leads numerous R&D projects across various sectors of the cryogenic industry. Supported by government grants, our R&D team is dedicated to reducing the dependency on imported military and defense micro and nano-technological equipment. Our ongoing projects aim to advance the field with groundbreaking innovations and cutting-edge technologies.

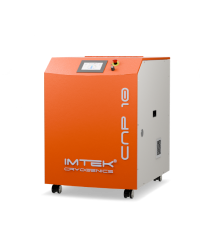

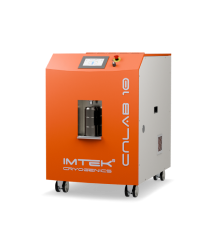

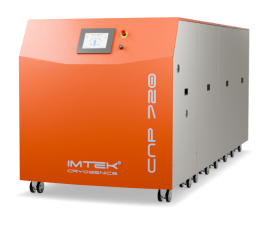

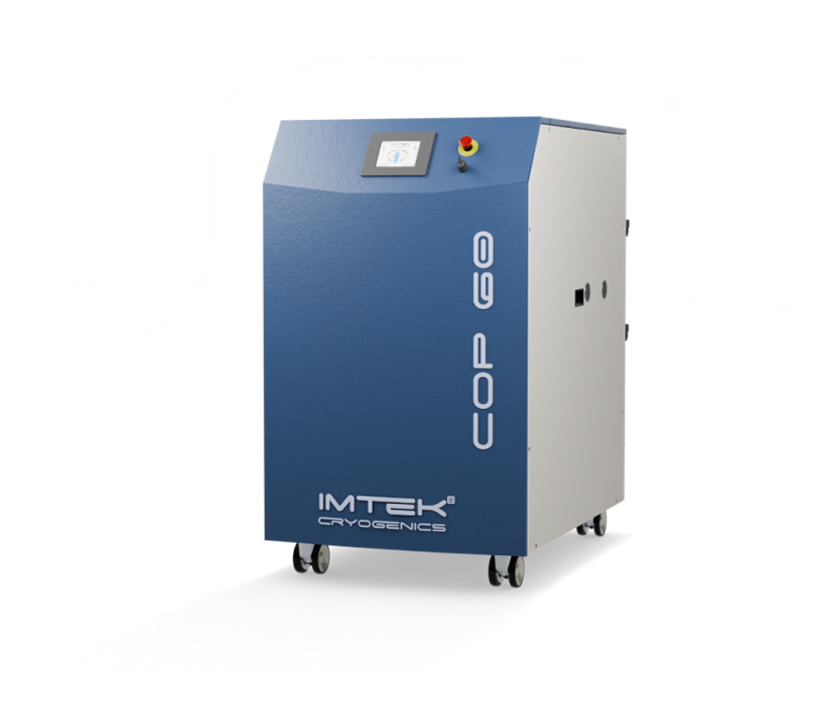

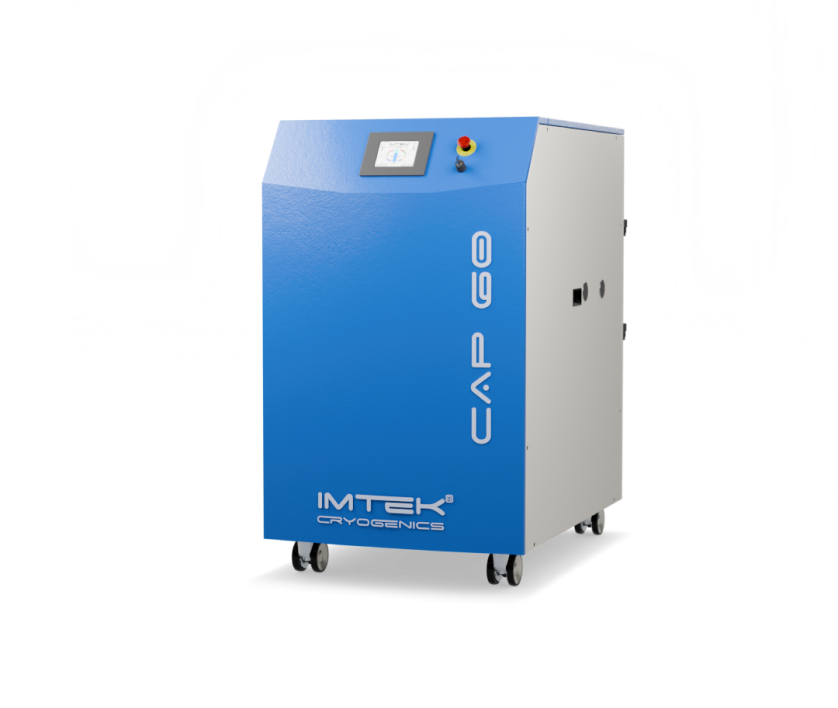

Progressive Design Language

IMTEK has developed its own Progressive Design Language, thanks to the expertise of our design team, which boasts over 50 years of accumulated knowledge in the cryogenics industry. Our design cycle focuses on fulfilling functional requirements while pushing the boundaries of innovation and aesthetics. Every component we produce is crafted with precision using our state-of-the-art CNC machines to ensure the highest quality and performance.

Advanced Machining Capabilities

At IMTEK, we house an extensive range of ultra-precise machining and honing tools, including 5-Axis CNC Milling Machines, Lathes, Plasma Cutters, Routers, Electric Discharge Machines, and Precise Laser Welding equipment. We manufacture parts with submicron cylindricality (±0.2 μm) tolerances and surface roughness Ra<0.05 μm. Our commitment to precision ensures that every component meets the highest standards of quality and reliability.

Eco-Conscious Innovation

Operating in a thermally stable environment with temperatures maintained at 22±0.5 °C, IMTEK takes precise measurements to minimize thermal variations. We constantly refine our ultra-precision machining processes to enhance quality. Every product, crafted using our advanced CNC machines, undergoes rigorous quality control to ensure it meets our exacting standards. Our dedication to quality ensures that IMTEK products are reliable, efficient, and built to last.

Stringent Quality Control

We promote sustainable practices and eco-friendly technologies across all our operations, striving to minimize environmental impact while enhancing energy efficiency.

Comprehensive Support and Consulting

IMTEK Cryogenics also offers extensive consulting services for the design, installation, and optimization of cryogenic and dispersion systems. Our technical support team provides in-depth training and maintenance services, ensuring seamless integration and peak performance of our cryogenic solutions.

Innovation at IMTEK

Join a team dedicated to pushing the boundaries of cryogenic technology and innovation.

Professional Growth

Experience continuous learning and professional development in a dynamic and supportive environment.

Impactful Work

Contribute to pioneering projects that make a real difference in the cryogenics industry and beyond.